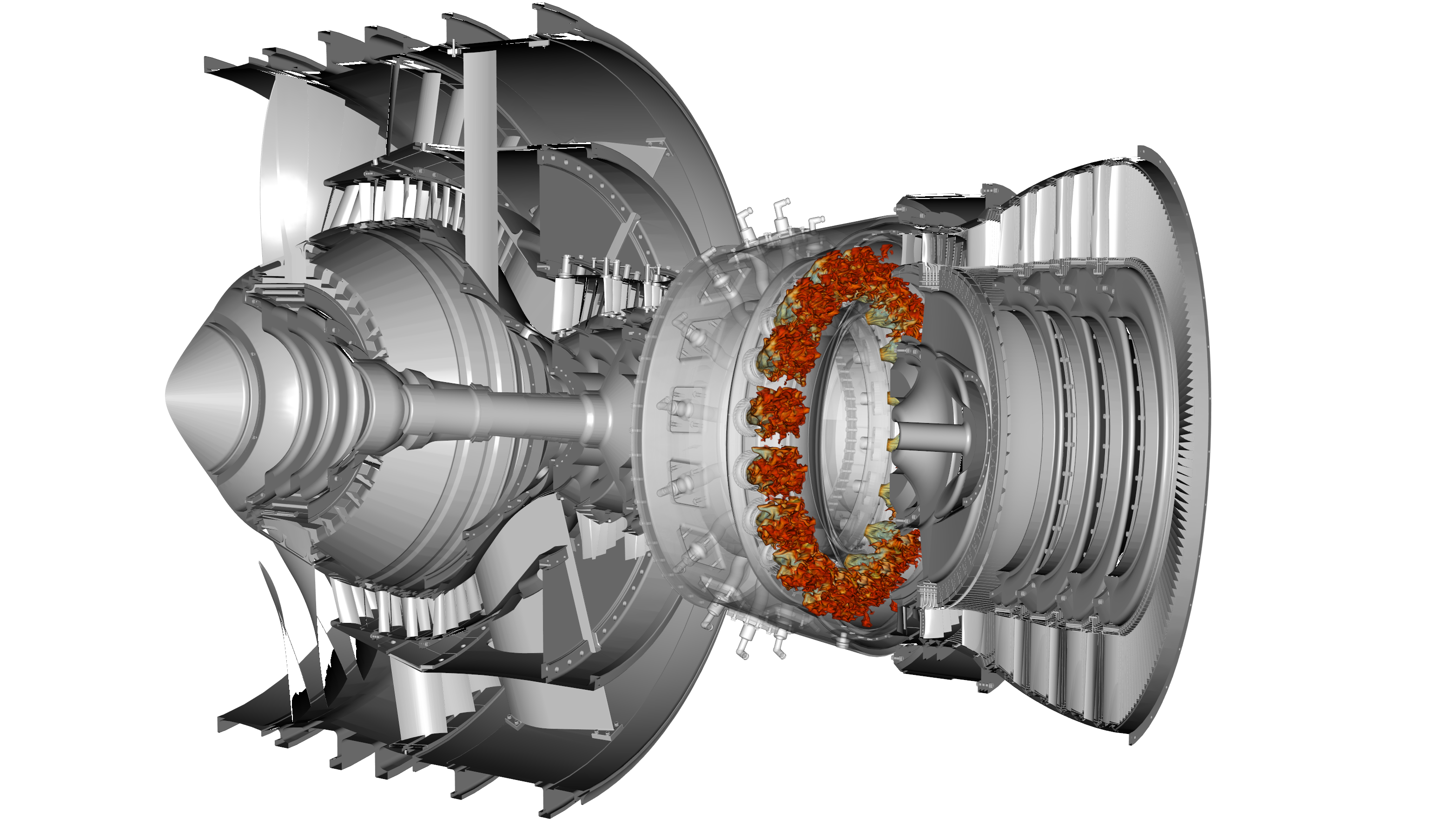

Modeling of Engine Combustion Processes Thomson Lab

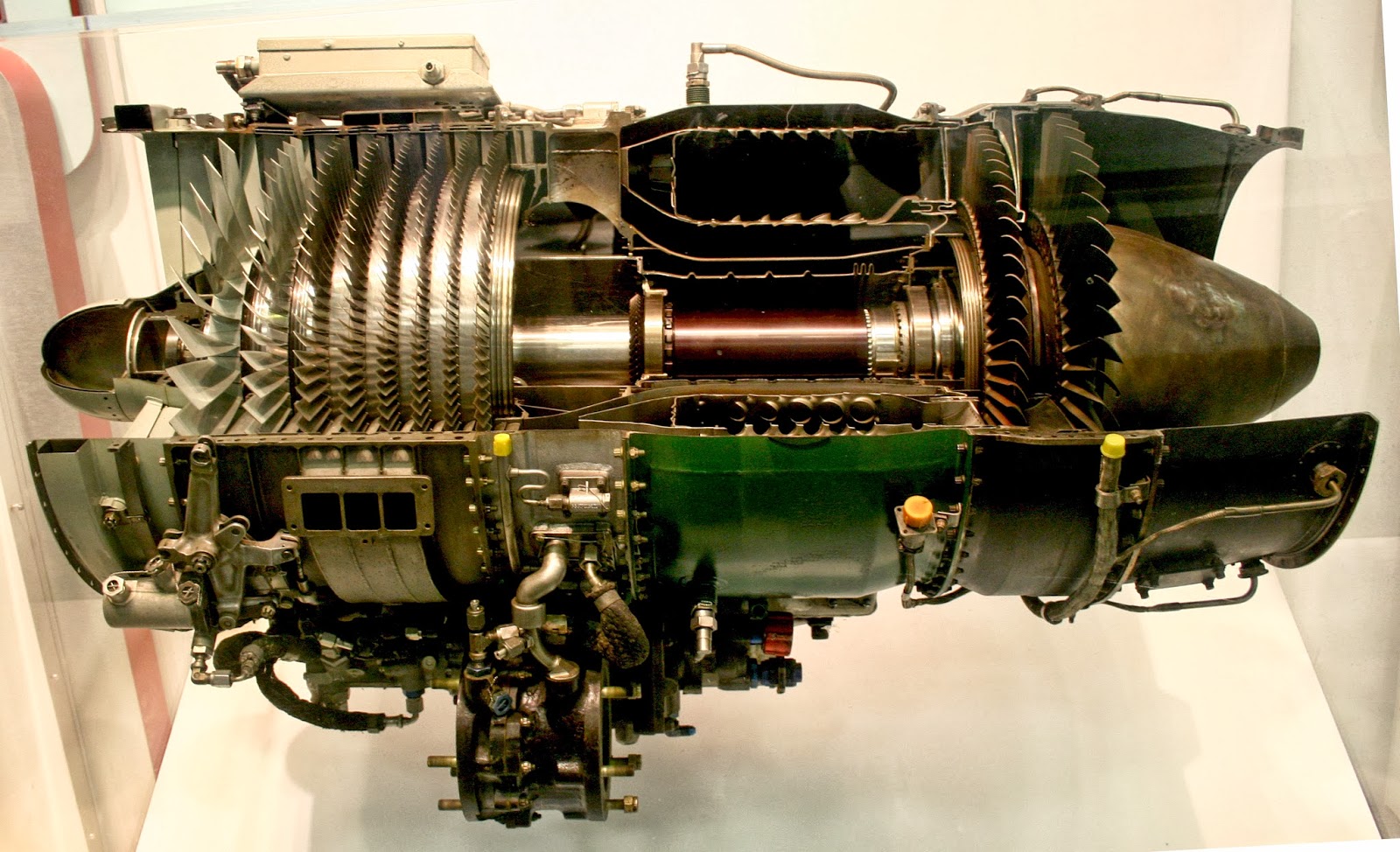

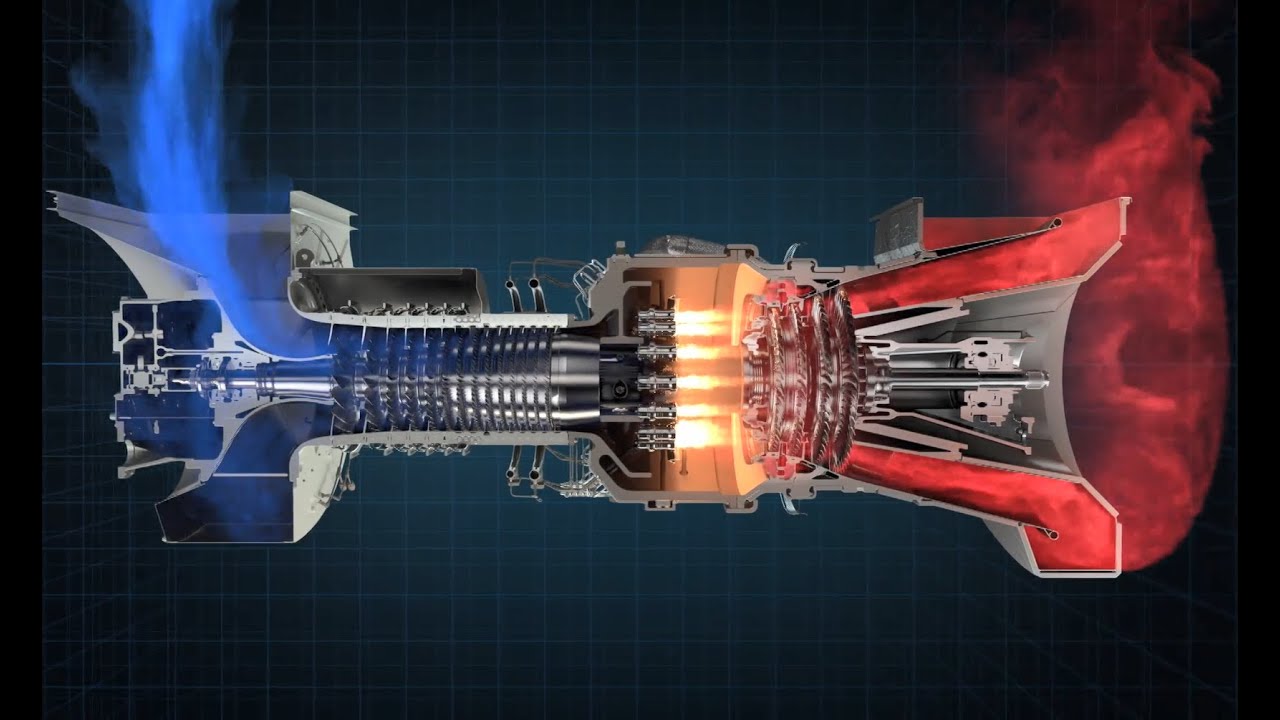

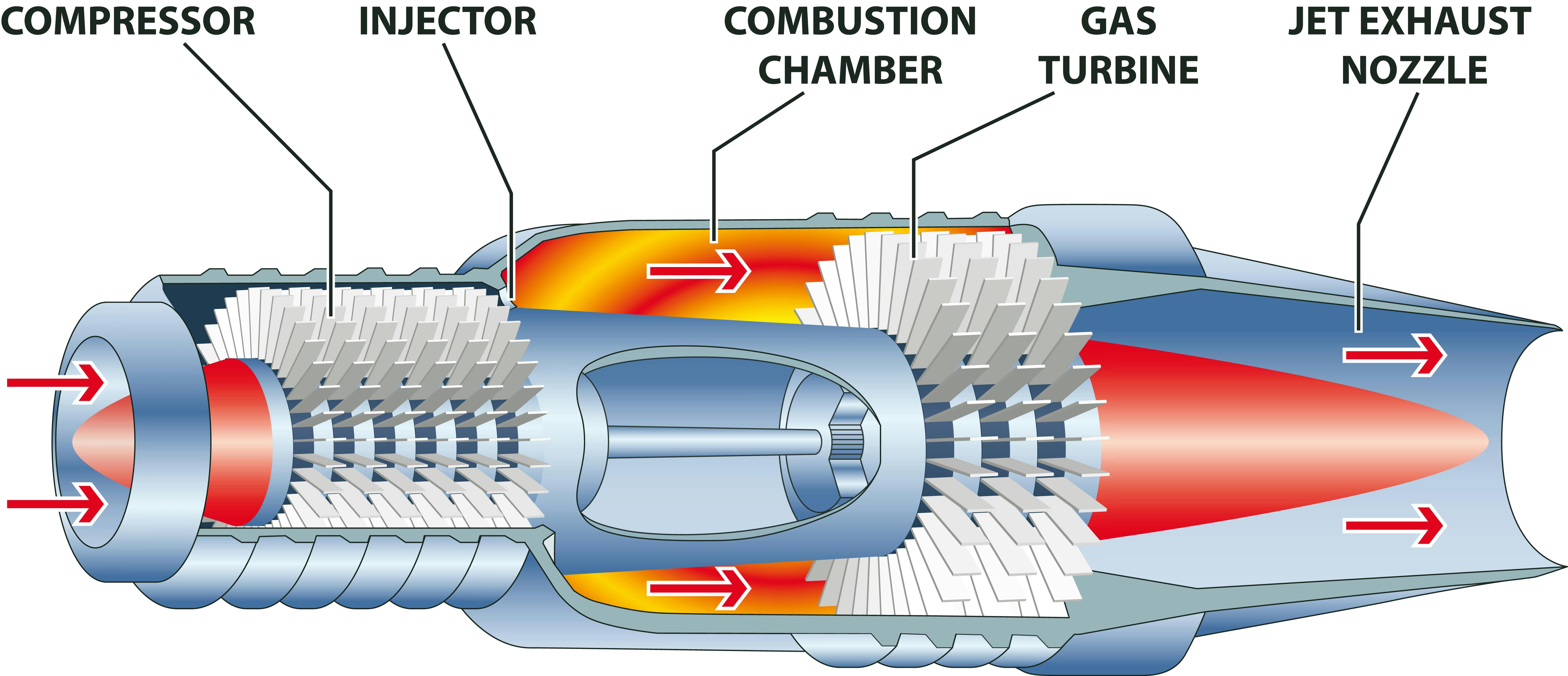

A gas turbine or gas turbine engine, by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. [1] The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: a rotating gas compressor a combustor

GASOLINE INTERNAL COMBUSTION ENGINE HISTORY Wroc?awski Informator Wroc?aw

A gas turbine engine is a device that is designed to convert the thermal energy of a fuel into some form of useful power, such as mechanical (or shaft) power or a high-. The absence of reciprocating and rubbing members, in comparison with internal-combustion engines, means fewer balancing problems and less lubricating-oil 1

Closeup of an Auto Part for an Internal Combustion Engine. Gas Turbine Stock Image Image of

In 1791, John Barber developed the gas turbine. In 1794 Thomas Mead patented a gas engine. Also in 1794, Robert Street patented an internal combustion engine, which was also the first to use liquid fuel, and built an engine around that time. In 1798, John Stevens built the first American internal combustion engine.

Barati Express adlı kullanıcının Green Energy panosundaki Pin Teknik

A gas turbine is an internal combustion engine that operates with rotary rather than reciprocating motion. Gas turbines are essentially composed of three major components: compressor, combustor, and power turbine.

ETN Hytrogen Gas Turbines 03 Hydrogen Combustion Turbine Logic

1.1. Sources of worldwide CO 2 emissions and potential of gas turbines (in 2010). In the aviation sector, propulsion is delivered principally by gas turbines, as mentioned earlier. There is massive political pressure to make air transport cleaner, both in terms of noise reduction as well as fuel reduction, and hence reduced CO 2 and NO x emissions.

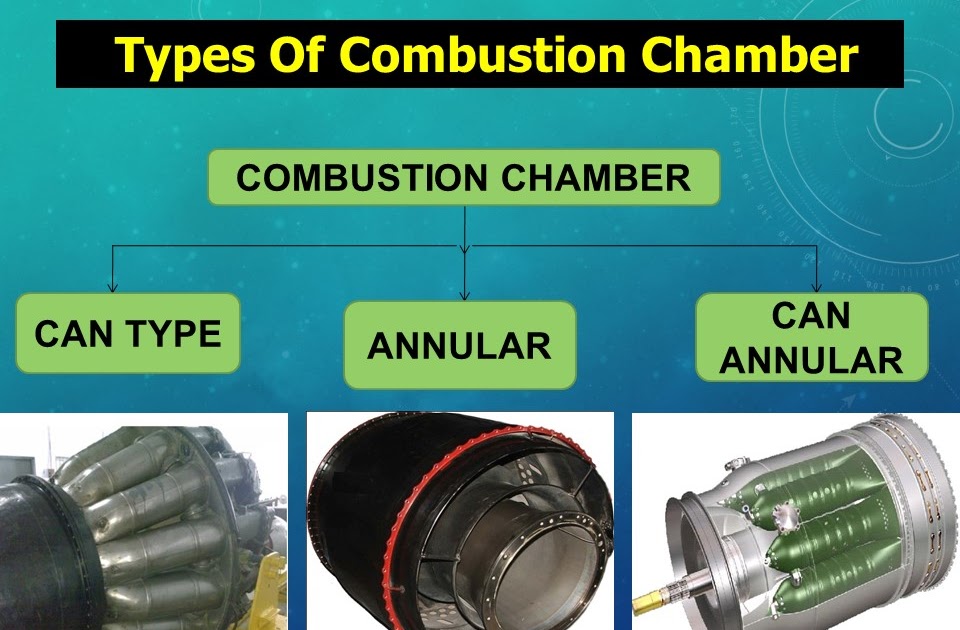

Types Of Combustion Chamber In Gas Turbine Engine Part 66 Preparation

CHAPTER 1 Review of Basic Principles (Pages: 4-44) Summary PDF Request permissions CHAPTER 2 Thermodynamics of Reactive Mixtures (Pages: 45-93) Summary PDF Request permissions Part II : Reciprocating Internal Combustion Engines CHAPTER II Reciprocating Internal Combustion Engines (Pages: 95-98) First Page

Closeup of an Auto Part for an Internal Combustion Engine. Gas Turbine Stock Photo Image of

The basic principle of the airplane turbine engine is identical to any and all engines that extract energy from chemical fuel. The basic 4 steps for any internal combustion engine are: Intake of air (and possibly fuel). Compression of the air (and possibly fuel). Combustion, where fuel is injected (if it was not drawn in with the intake air.

Center for Environment, Commerce & Energy Natural Gas Combustion Turbines

phenomenon known as "turbine combustor lean blowout." As the CT generators accelerated in response to the frequency excursion, the direct-coupled turbine compressors forced more air into their associated combustion chambers at the same time as the governor speed control function reduced fuel input in response to the increase in speed.

The Difference Between Gas Turbine and Gas Engine Linquip

In this video, I explained Advantages And Disadvantages Of Gas Turbines Over Internal Combustion Engine.Chapter: Thermal Power PlantPlaylist of Thermal Power.

Combustion Siemens Software

An internal combustion engine is a type of heat engine that is widely used in various applications, particularly in transportation. This engine acts as the primary power source for automobiles, motorcycles, airplanes, boats, and many other machines.

[DIAGRAM] Diagram Of Gas Turbine Power Production System

Gas turbines are a type of internal combustion (IC) engine in which burning of an air-fuel mixture produces hot gases that spin a turbine to produce power. It is the production of hot.

1 Gas Turbine Introduction Turbine Internal Combustion Engine

A Gas Turbine is a type of engine that converts fuel into mechanical energy by combustion in a turbine. In a gas turbine, fuel is mixed with air and burned in a combustion chamber. The hot exhaust gases are then passed through a turbine, which drives a generator to produce electricity or mechanical energy.

What Is a Combustion Turbine? (with pictures)

How does turbine efficiency compare with internal combustion engines if all the turbine power is converted to mechanical energy? When looking at conversion from chemical energy into mechanical energy: very favourably. The early turbojets had low thrust efficiency, they could not convert their gas generator power into thrust in an efficient way.

Material types used in different sections in an Alstom gas turbine... Download Scientific Diagram

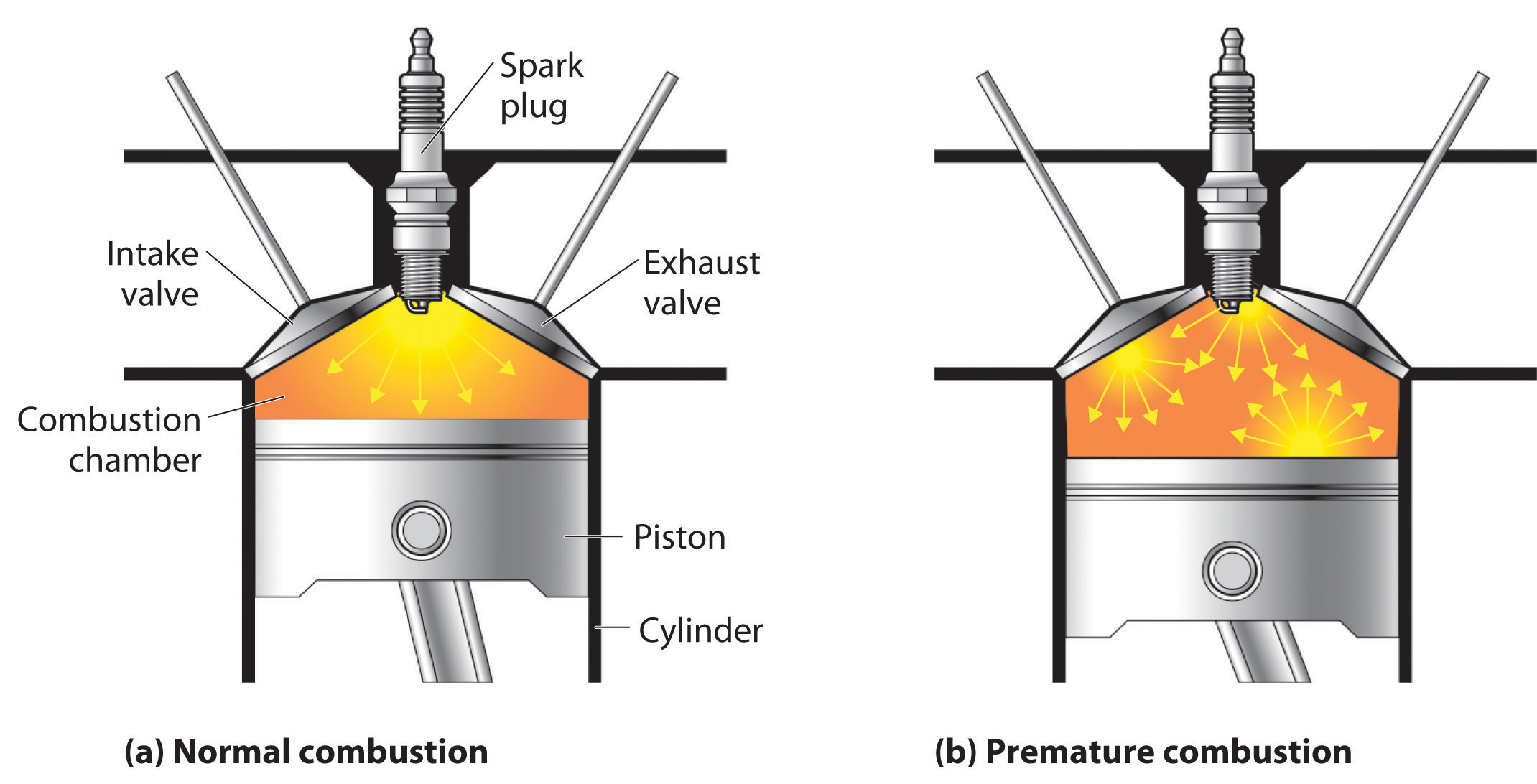

The internal combustion has taken on many different forms throughout its long, greater than 150-year history, but combustion has always been one of its few constants. Indeed, combustion is even in its name and helps differentiate it from other thermodynamic work devices such heat engines and fuel cells. Type.

Combustion section transition pieces that direct hot gasses onto the turbine blades of a

Abstract. The current article introduces a physics-based revolutionary technology that enables energy efficiency and environmental compatibility goals of future generation aircraft and power generation gas turbines (GTs). An ultrahigh efficiency GT technology (UHEGT) is developed, where the combustion process is no longer contained in isolation between the compressor and turbine, rather.

Jet Engine Major Components How Do They Work? Xometry

gas-turbine engine, any internal- combustion engine employing a gas as the working fluid used to turn a turbine. The term also is conventionally used to describe a complete internal-combustion engine consisting of at least a compressor, a combustion chamber, and a turbine. General characteristics